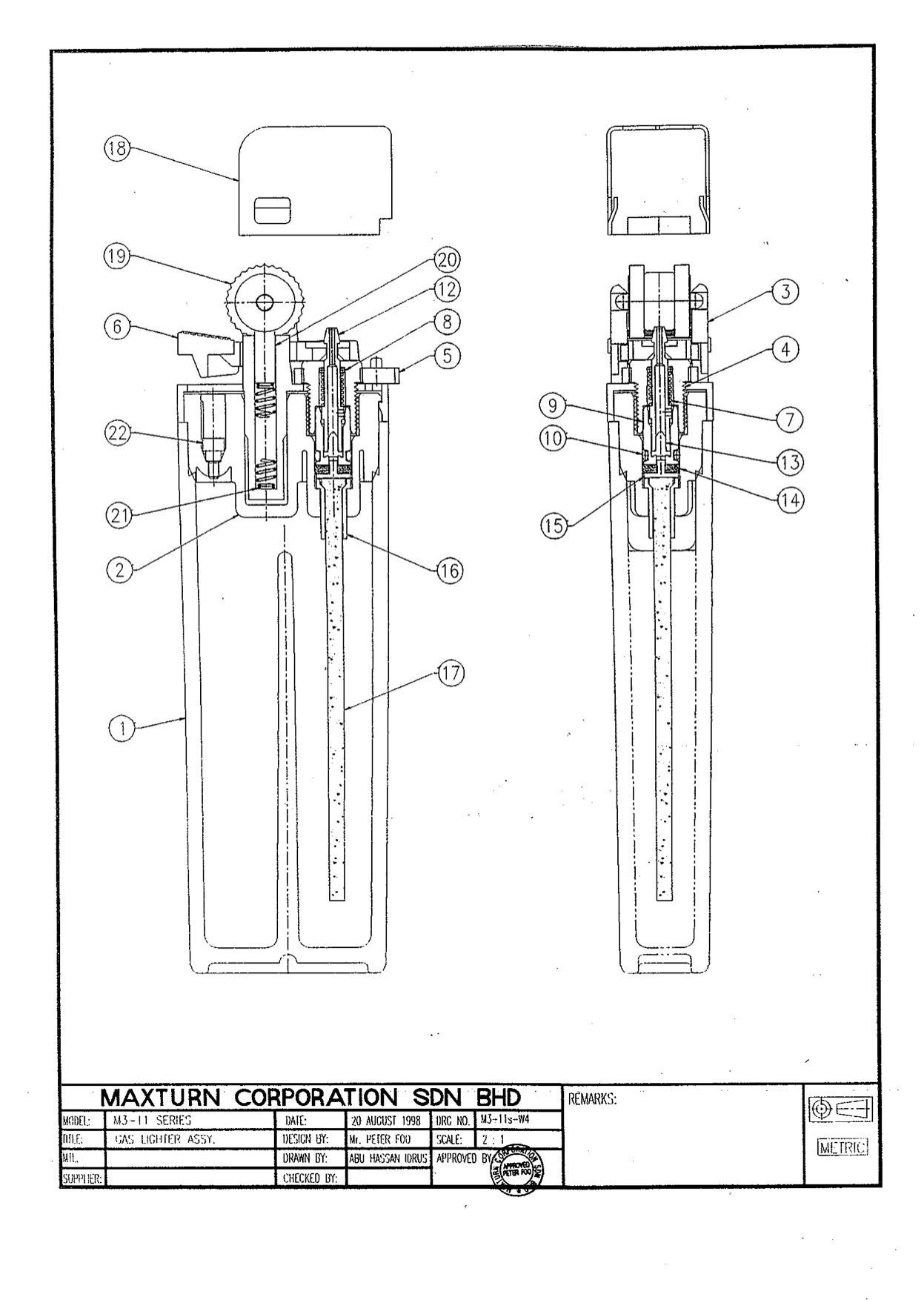

1. LIGHTER DESIGN

We have our in-house gas lighter design team to come up with new models periodically as well as to improve the products quality as continuous efforts to stay at the competition of marketplace.

2. TOOLING

We have our internal tooling department to take care the products tooling to ensure regular maintenance to ensure top and precise quality products injected from Injection Department.

3. INJECTION MACHINES

We have 12 Injection Machines with auto-robotic arms, which can have the capacity output of 15 million pieces per month.

4. ULTRASONIC WELDING

Our ultrasonic welding department can provide a very stable output of 65-70 pieces per minutes and can provide the capacity of 15 millions pieces output of gas lighter per month capacity.

5. AUTO-CAPPING

We are using semi-auto capping to assembly the gas lighters with a simple assembly machines with the capacity of 400,000 pieces per day.

6. PACKING

We have gone through the stringent QC & QA inspections and upon approvals from the respective departments will only come to the final packing for deliveries.